Production process tracking information

Timely process information, quality inspection and grading information

Production line shutdown information

Can perform rolling delay production statistics in a timely manner

Timely display of the mass curve of the steel coil

Statistics of various process information

All types of classes/day/week/monthly reports

System introduction1. PDI and scheduling module: Strengthen the management and scheduling of PDI can be adjusted quickly to strive for production continuity

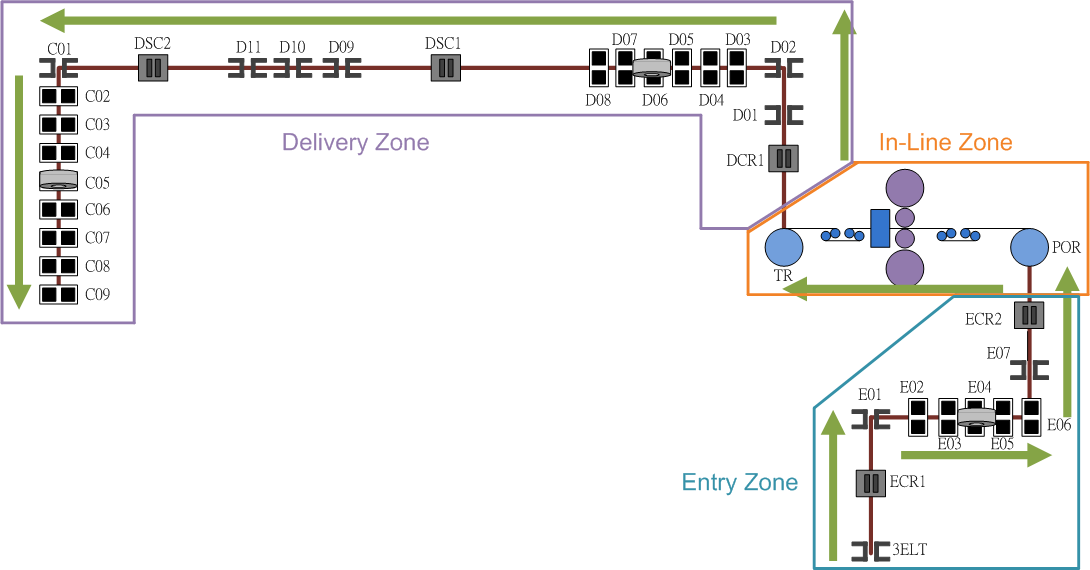

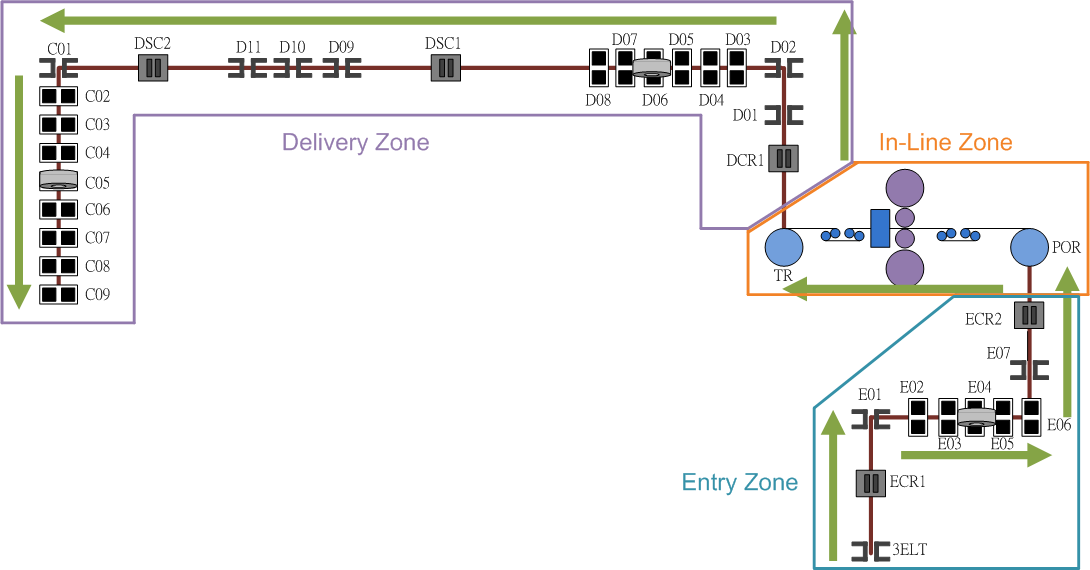

2. Production process tracking module: Provides graphical interfaces to timely present various equipment information for current production process tracking

3. Electronic control mode setting module: It can provide table lookup mode, build standard processes, and automatically set up to meet a small number of diverse order-taking production

4. Class report management module: Automatically generate daily class divisions to reduce personnel errors and manual time-consuming establishment.

5. Production delay management module: Automatically record shutdown information, personnel can select abnormal situations, effectively grasp the processing time

6. Process information collection module: will produce process data in a timely manner, and use systematic and efficient classification planning to ensure that data is not missed, so as to improve the big data of process information.

7. Equipment online integration management module: Receive rolling process information to the system for subsequent processing, or throw the message to other systems through the process information reception and transmission module. Its interface includes SOCKET, FTP, DATABASE, network franchise, RPC, DI, etc.

8.ERP online integration management module: receive hot-rolled steel coil information into the system for subsequent processing, or throw information to other systems through the process information reception and transmission module. Its interface includes SOCKET, FTP, DATABASE, network franchise, RPC, DI, etc.

9. Quality inspection management module: summarize quality statistical information based on production process data, and provide personnel inspection and judgment

10. Roller maintenance management module: It can receive external roll data or manually set up by personnel, and record roll-related usage records based on production process data, establish complete roll maintenance management, and improve prevention and maintenance results.

Customer CasesZhonglong: No.1 Hot Rolling Finishing Program Control Computer System (#1TNRL)

Zhonglong: No.2 Hot Rolling Finishing Program Control Computer System (#2TNRL)

Zhonglong: No.3 Hot Rolling Finishing Program Control Computer System (#3TNRL)